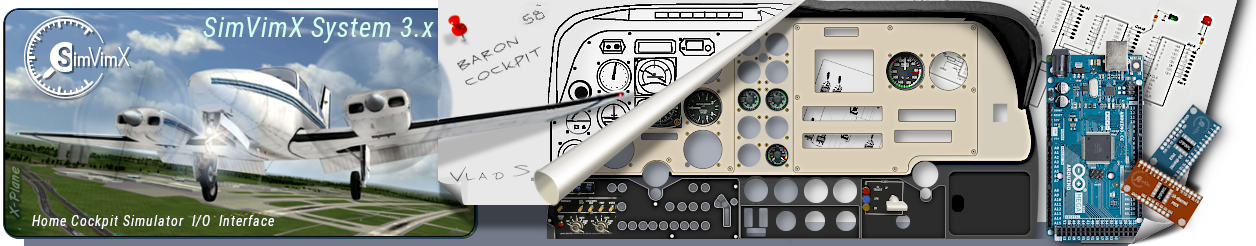

For the glareshield I've used 3mm PVC sheets as outer surface and PVC wall panels as inner honeycomb filler. In result, the whole construction has turned stiff and light. Initially, the glareshield was covered with leatherette (dermatin) on glue

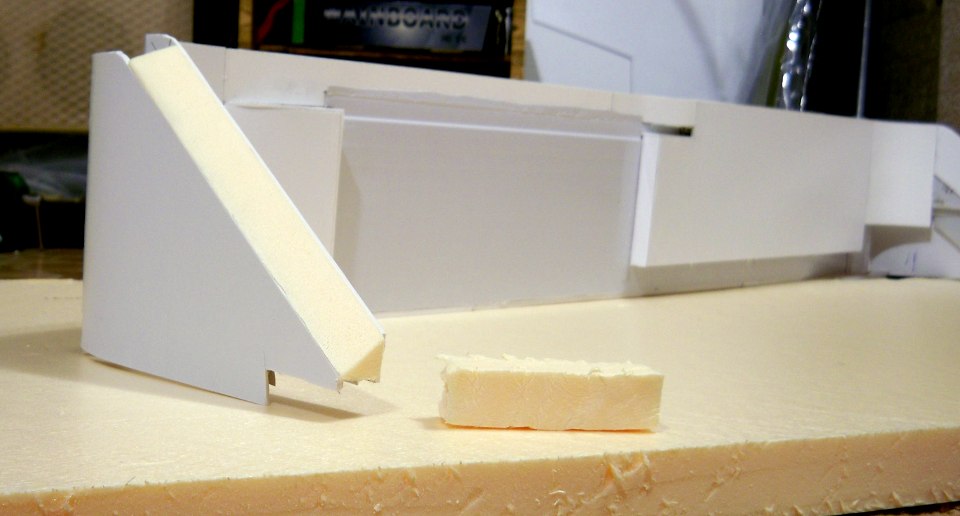

The disadvantage of this method is that it is hard to achieve the tight fit of the covering to the surface in the places of bends, and dermatin gathers the folds...

Unhappy with the result of leatherette coating, I decided just to paint the glareshield. The glued dermatin was torn off, glue residue and roughness of the surface was sanded. To give the edges necessary forms, the wood and plastic inserts was used and coated by epoxy putty.

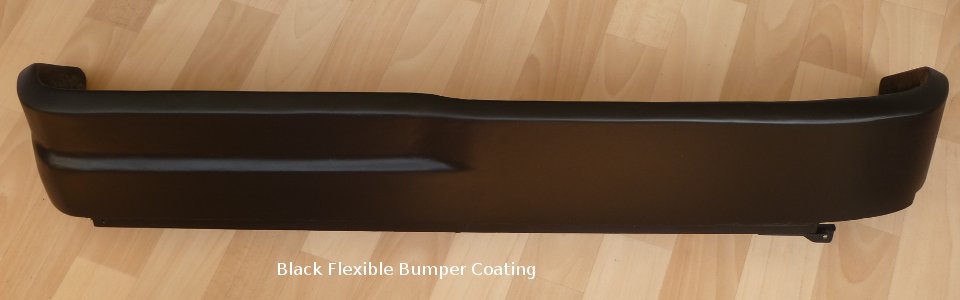

The whole thing was thoroughly sanded, coated by black primer, sanded again, and then painted by black "Flexible Bumper Coating" aerosol.

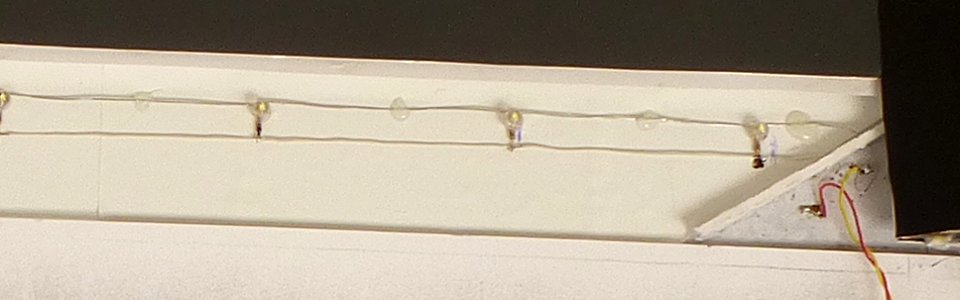

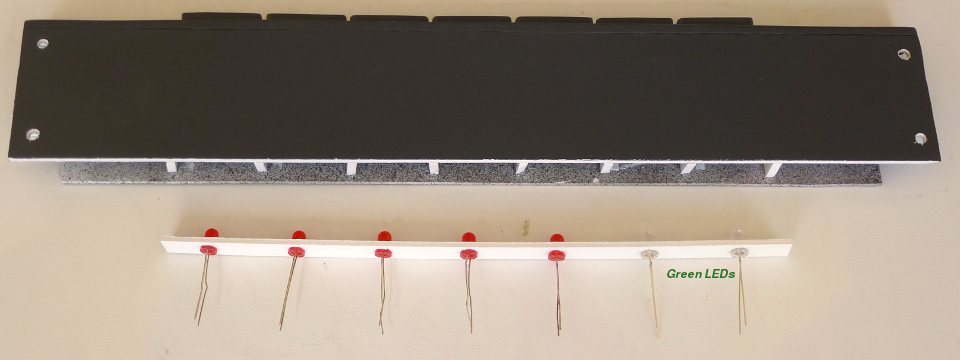

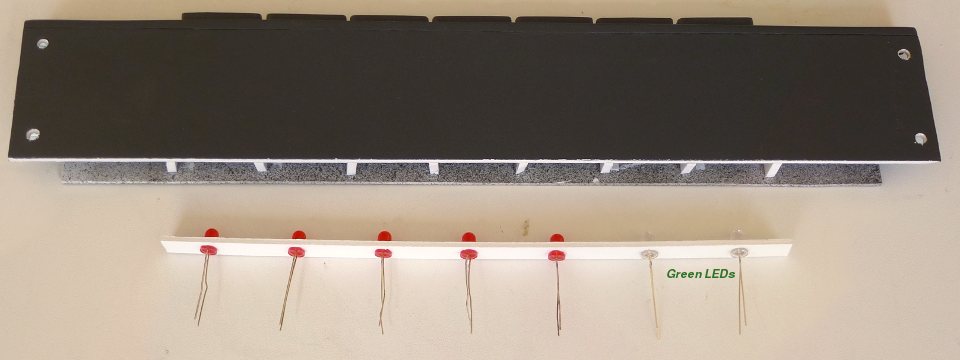

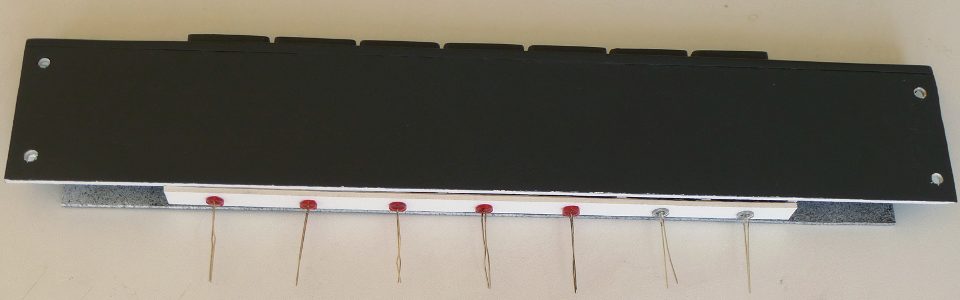

Flood lighting (10 LEDs behind the white plexi strip):