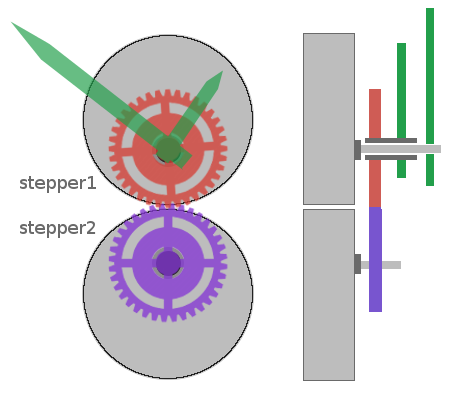

If you need a two-needle instrument but don't have a suitable mechanism for one stepper or multi-shaft steppers, you can use separate steppers for each needle with additional gear wheels.

Both gear wheels have to be of equal diameter:

The second (bottom) stepper can have a zero-position sensor disc directly on its shaft.

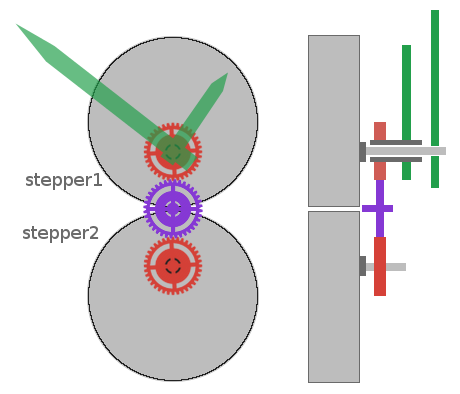

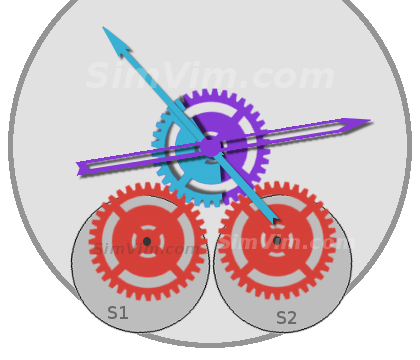

One stepper motor should be configured with inverted mapping. To avoid this, you can add a 3rd gear wheel as shown in the picture below. Or, any other gear combinations can be used, depending on your gauge design (for example, when you have two co-axial needles with gears as in the right picture:

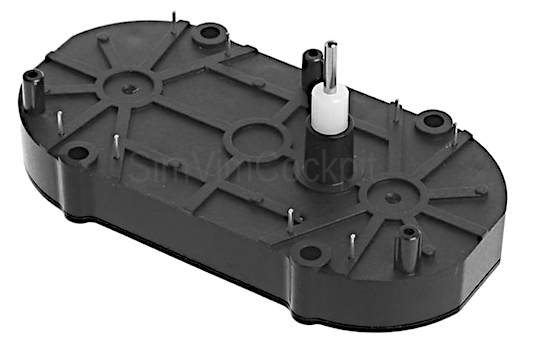

Of course, the obvious option is to buy one of available on market biaxial stepper motor, for example, VID28-05, BKA30D-R5 or similar. These are just two motors in one housing with gearboxes like the ones shown above:

You can find them for $3-4 for a piece, hHere are few example links (relevant on the dat this post is published or updated):

On AliExpress 1